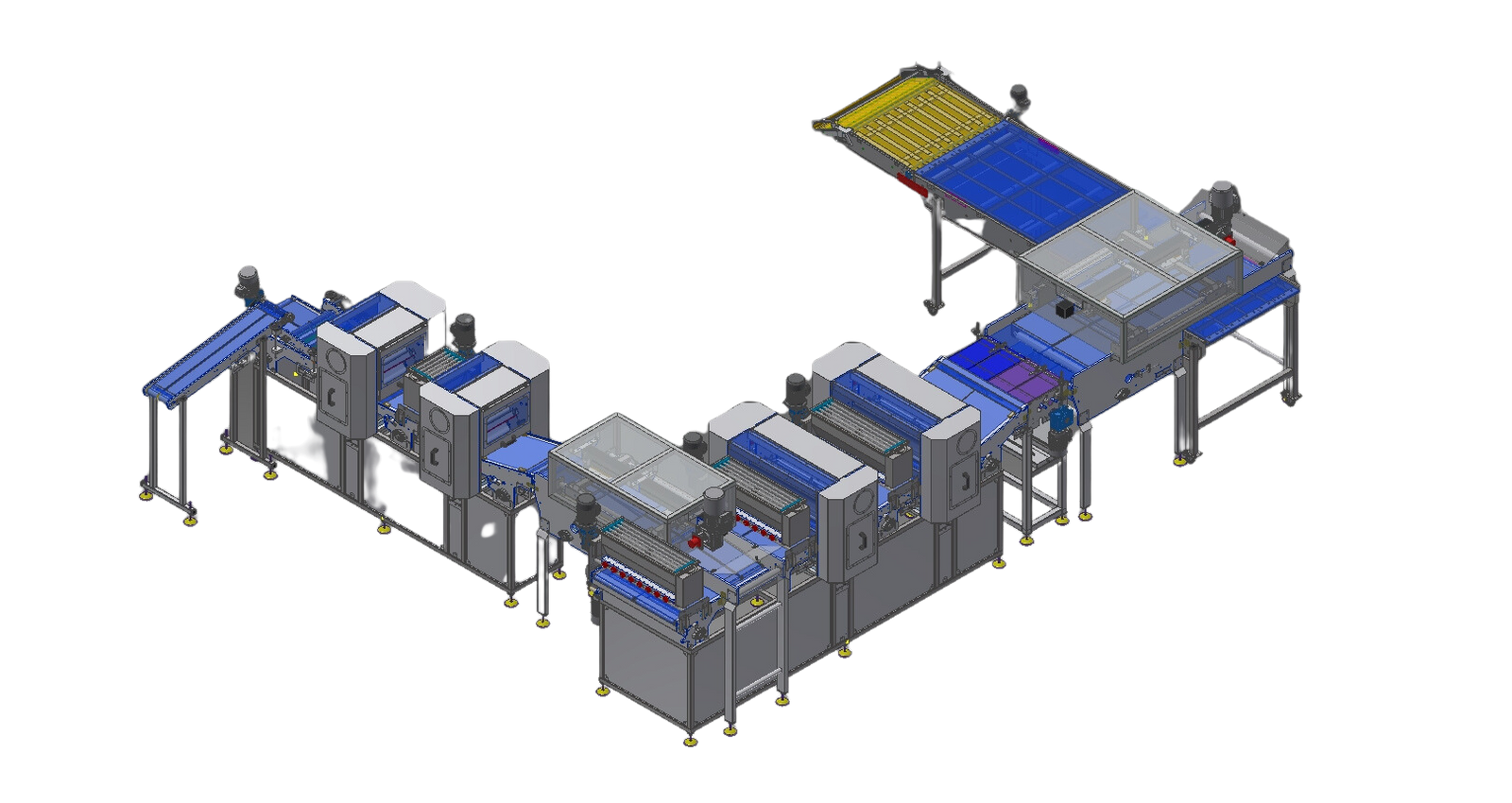

These plants are intended to form and shape the dough precisely and evenly, to obtain high quality products with excellent taste.

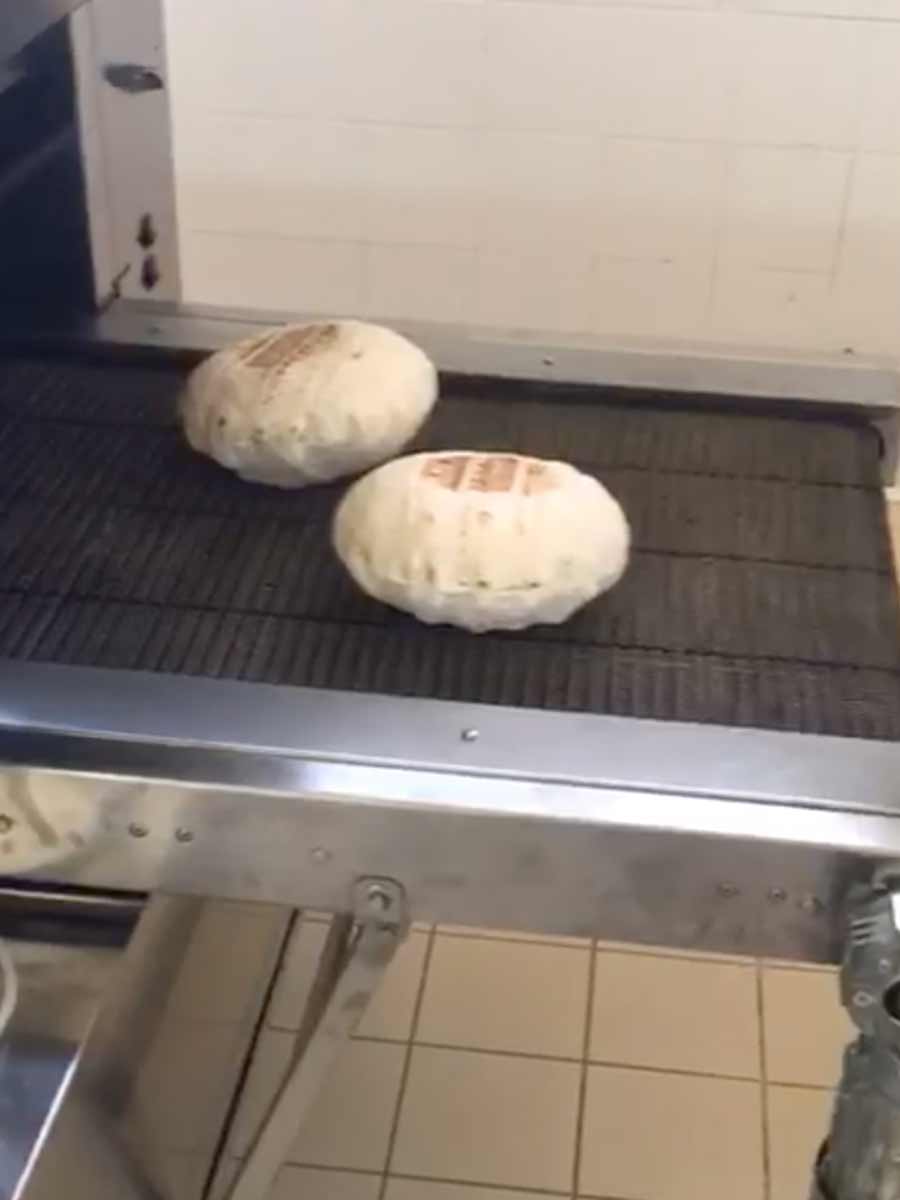

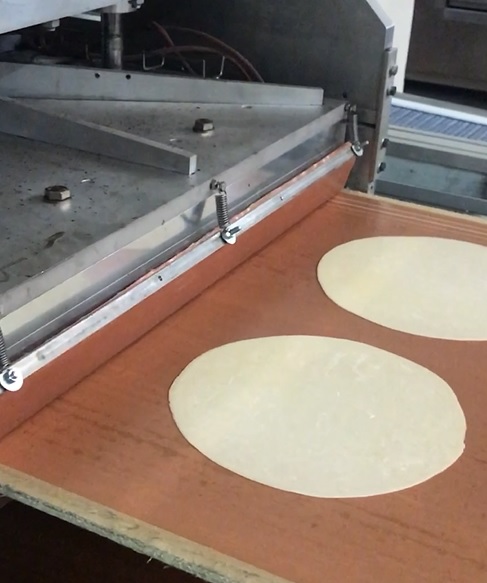

Dough forming plants use a series of rollers, Blades, Punches and other tools for manipulating and kneading the dough. For example, bread making machines use rollers and blades to cut the dough into specific shapes, such as sandwiches, slippers or baguettes.

Dough forming equipment can also be equipped with extrusion systems, to produce doughs of particular shape, such as those used for the production of biscuits or sweets.