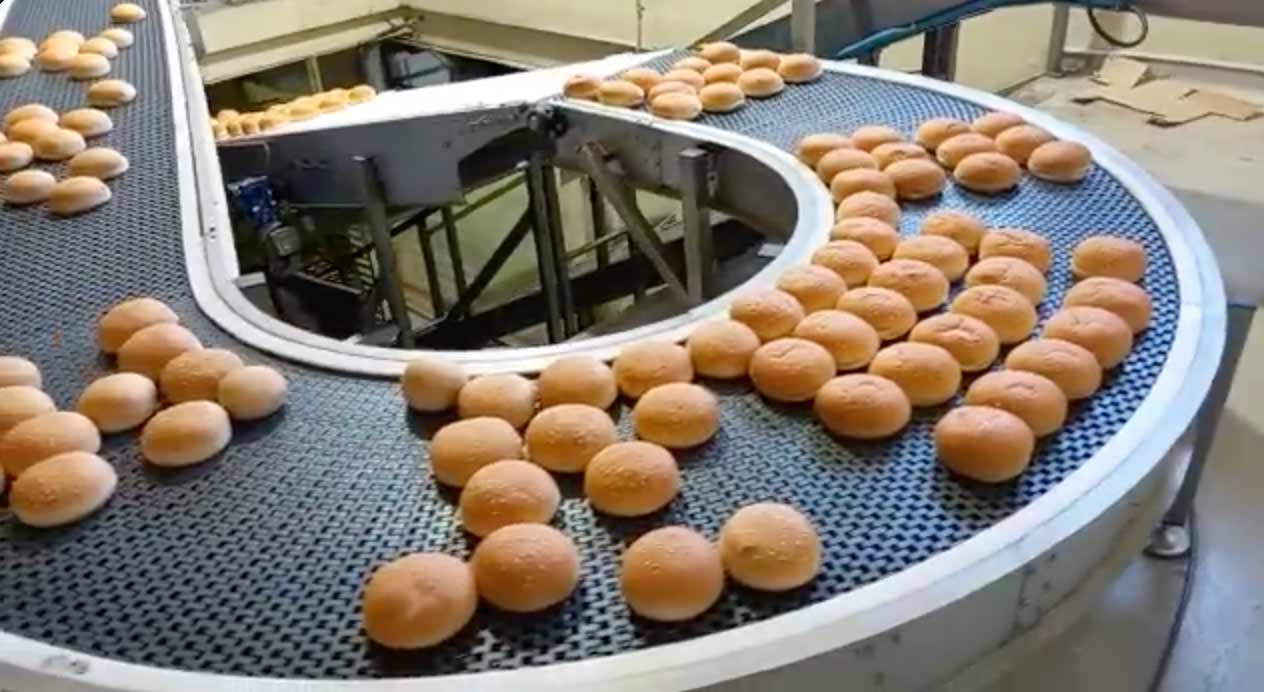

Automation in the food industry refers to the use of Advanced machinery and technologies per semplificare e ottimizzare i processi di produzione alimentare.

Our automated machinery allows and increase efficiency, reduce production costs, improve food quality and safety, and comply with industry regulations.